EMS | THE FLEXIBLE INNER SOCKET DESIGNED TO FIT WITHOUT SLIPPING, BUNCHING, SQUEEZING OR DISCOMFORT

2023 Innovation Award Winner

November 16th, 2023 – NETTwork Manufacturing awarded the GSDC Innovation Award (iAward) for their development of the Enhanced Mobility Socket (EMS).

NEVER WALK ALONE — In a world where every step is a challenge, a simple innovative socket system serves as a beacon of hope, transforming the lives of amputees. Amidst their emotional battles, this miraculous invention offers a comforting embrace, healing not just their bodies but their hearts.

These extraordinary individuals gain more than just the ability to walk with ease; they find the strength to confront their inner demons and shed the shackles of self-consciousness. With newfound confidence, emerging as warriors, they teach us the power of resilience and self-love.

EMS | The Enhanced Mobility Socket

What is the EMS multi-surface flexible inner socket?

The Enhanced Mobility Socket (EMS) is a flexible inner socket designed to improve the performance and function of transtibial (below knee) prosthetic leg systems.

REQUEST A FREE MATERIAL SAMPLE

We welcome you to request a free sample of the materials used to build these custom sockets and liners. Feel the difference for yourself!

We welcome you to request a free sample of the materials used to build these custom sockets and liners. Feel the difference for yourself!

Benefits To Using the Enhanced Mobility Socket System

Healthier

EMS improves the patient’s limb health.

Stronger

EMS provides a strong connection to the prosthesis.

Controlled

EMS increases control over the prosthetic leg.

Aware

EMS heightens spatial awareness.

Comfortable

EMS controls and stabilizes moisture.

When Movment Matters, Trust EMS.

An amputated limb inevitably comes with impaired sensation and higher susceptibility to issues within the prosthetic ecosystem, comprising of pressure, moisture, friction, and restraining devices (vacuum, suction, pin system). The balance of these attributes determines quality of life. When imbalanced an amputee can expect to develop sores, ulcers, skin breakdown and tissue or muscle atrophy, potentially leading to infections or even more surgery. We understand the importance of maintaining reliable comfort and provide solutions that last.

The EMS Custom Socket Sytem

EMS FLEXIBLE INNER SOCKET

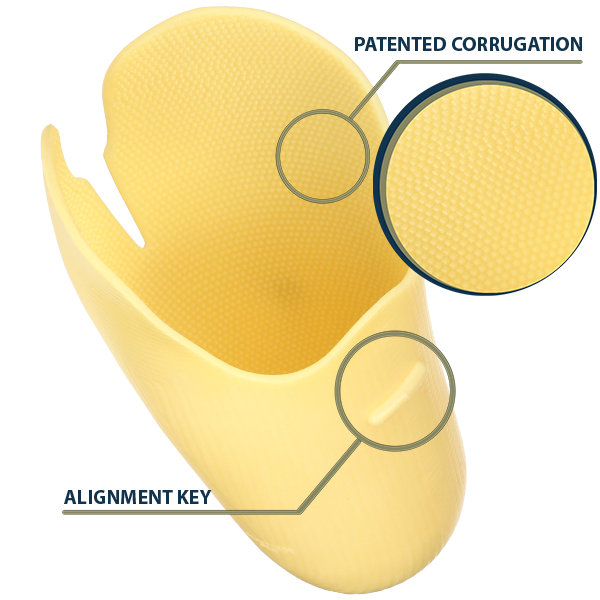

The unique and patented corrugations inside the socket increase hold by 100% over smooth sockets and increase surface area by 400%, which means patients can have confidence in a snug fit, without squeezing the limb.

Further, the Supracondylar Aspect of the EMS creates additional suspension, allowing for a heavier and more modern prosthetic foot, ankle, and pump while significantly reducing pistoning. The prominent alignment key on the back of the socket allows for a consistent fit and feel every time the EMS is put on.

PATENTED TECHNOLOGY

EMS sockets give amputees confidence to move freely without worry. The patented liners, as well as the patented socket texture, allow the socket to stay in place without excessive squeezing of the limb. This carefully maintained vacuum environment is proven to improve limb health by reducing moisture buildup and skin irritations, and a healthier limb means a more active lifestyle. EMS strengthens the connection to the prosthesis which provides a superior amount of control for the user and heightens proprioception and spatial awareness.

The EMS Custom Liner System

EMS PATENTED URETHANE LINER

The micro-ribbed technology provides a strong connection and wicks away moisture. The preflext ribbed liner prevents bunching and drooping of the liner with movement. The urethane material is durable, easy to clean, and reduces skin irritation. Every Liner manufactured is customized to specifically fit each patient.

It’s obvious…

What provides a better fit? A straight tube sock on your foot, or a fitted crew sock with a heel? The shape of the heel actually prevents the sock from bunching up around your ankle. The same goes for the EMS System. This liner is designed to contour the patient’s limb to fit without the materials bunching up behind the knee, providing reliable comfort.

The EMS Guarantee

The EMS Multi-Surfaced Flexible Inner Socket is the most reliable way to ensure a patient’s prosthetic limb remains securely in place. While our proprietary material and manufacturing process has proven to produce durable inner sockets second to none, we understand that sometimes things happen.

Every EMS inner socket comes with a six-month warranty which begins the day your order ships. We value each and every customer & we appreciate the opportunity to assist in providing a better quality of life for amputees.

OUR MANUFACTURING PROCESS

Every EMS is custom made to fit each amputee’s specific shape by using a cast of their residual limb, taken over their liner of choice. After we receive the cast, we pour the positive which is then scanned and transformed into a 3D model that is accurate to thousandths of an inch. This intimacy guarantees, out of the gate, a superior product to one that is merely hand measured. Every order is produced locally and shipped promptly to the Prosthetist for the final fitting with the patient.

EMS | Patient Success Story

Thank you to Cornerstone Prosthetics & Orthotics for your support!

A division of NETTwork Manufacturing, Inc.

Office: (320) 654-8352

40091 County Road One, Rice, MN 56367

Why Trust The EMS Socket System?

Other socket systems are rigid and non-dynamic, therefore unable to accommodate volume changes that naturally occur throughout the day. These systems use compression and pressure to hold the prosthetic in place, increasing potential for discomfort during volume changes.

The EMS System corrects this issue using increased surface area and friction coefficiency to create negative pressure and flexible load distribution, allowing the patient to comfortably maintain volume. Combined with its other features, the EMS provides amputees with a consistent and reliable connection.

With an inferior system, something as simple as sitting can be uncomfortable for an amputee. By balancing fluid changes within tissue, decreasing moisture accumulation around the skin, and accommodating for muscle movement, the EMS can provide ease, movement and freedom that other systems may not be able to.

US Patent Numbers Include: US8758449B2, US8114167B2, US20120173000A1, US20040181290A1